TAKA Material & Systems Laboratory, inc.

TL-COLOR

UV Fluorescent Materials -Industrial Application-

Through integrated approach from the synthesis of special luminescent pigments and dispersion stabilization to the ink optimization for each printing methods and applications, TAKA Material & Systems Laboratory inc. has successfully developed revolutionary UV fluorescent ink that has unparalleled security performance and expression power at the same time.

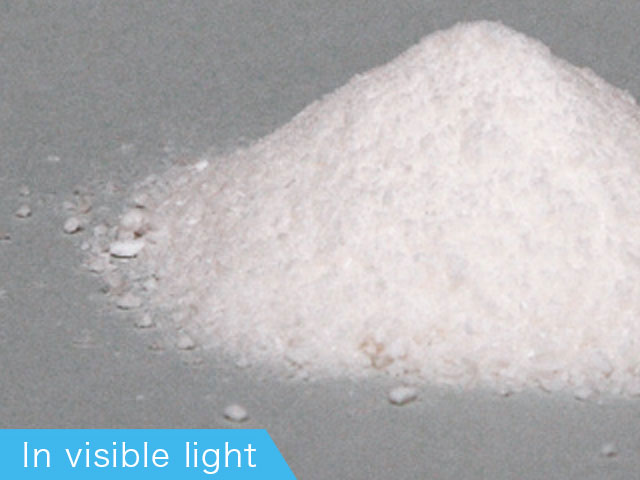

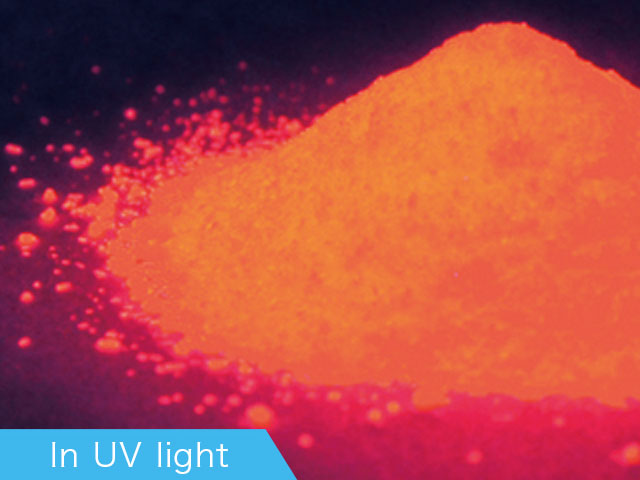

Pigment Synthesis Technology

Successfully developed unique pigment that is clear and transparent in the visible light and glows with incomparable brightness in UV light.

While demonstrating superior stealth performance, it glows with astonishing luminance when exposed to UV light assuring unbeatable visibility.

These special luminescent pigments, with a special chemical treatment, realize three primary colors of light, i.e. red, green, and blue.

This has enabled to create full-color expressions, which was difficult with conventional fluorescent ink.

Dispersion Stabilization Technology

TAKA’s advanced technology has achieved precise particle size control and optimized dispersion process, realizing TAKA’s dispersion stabilization technology that prevent pigment sedimentation and degradation of color.

TAKA has largely improved latitude in ink design, generating opportunities to adjust pigment dispersion to ink property required.

Sophisticated Ink Formulation Technology

With these technologies, TAKA is capable of ink design optimization for various types of printing methods, i.e. offset, flexographic, gravure, silk screen, and inkjet (water-based, oil-based, and UV-curing type). For this reason, TAKA’s TL-COLOR can be used for printing on various kinds of media, including paper, plastic, ceramic, wood, etc.

For Inkjet printing, in particular, though it is said difficult to maintain stability, TAKA’s technology can largely improve print process productivity by configuring ink to the printing head.

Fine-tuning for Diverse Application

TAKA Material & Systems Laboratory has developed TL-COLOR Management System with its proprietary Proof System as a core. This maximizes the performance of TL-COLOR Ink and enhances the value of the printed materials.

- Silk screen printing machine

- offset printing machine

- large-format inkjet printer