Metalic Inkjet Ink

TAKA Material & Systems Laboratory, inc.

Metalic Inkjet Ink

TAKA Eco-Solvent Inkjet Metallic Ink – Printing Sample

Conventional aluminum flake dispersion concentrate, such as ECKART’s “Metalure” Series and BASF’s

“Metasheen” series, has been available in the market for quite some time.

However, these conventional products were not suitable for inkjet ink due to:

TAKA Metallic Dispersion developed by TAKA Material & Systems Laboratory, inc. has paved a new path to the development of metallic-color ink for inkjet printer.

When pulverizing evaporated aluminum into flakes in the process of dispersion liquid production,

We control particle size of aluminum flake and apply special dispersion treatment.

Here, we use organic solvent that is highly wetting and permeable, less damaging against head

materials, and desiccation-resistant to secure stable dispersion.

This method provides us with dispersion liquid optimum for inkjet ink development

to realize maximum brightness.

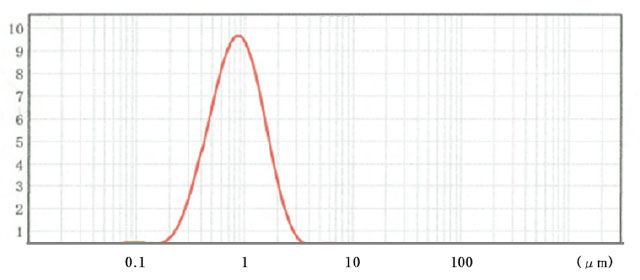

Particle Size of TAKA Metallic dispersion distributes in a narrow range around 1μm showing small variation.

Particle Size Distribution of TAKA’s Aluminum-flake dispersion

TAKA has engineered Eco-solvent Inkjet using TAKA’s Metallic Dispersion Liquid. To engineer Inkjet Ink, composition must be optimized to accomplish:

Especially, metallic ink is required to accomplish the above mentioned mission at advanced level to obtain maximum brightness.

TAKA’s Eco-solvent Inkjet Metallic ink generates printed image of excellent brilliance as the aluminum flakes become oriented in uniform direction on a photo paper. Also, it can generate metallic printing on PVC-base media.

With the metallic dispersion developed by TAKA, TAKA’s engineers with complete understanding on the characteristics of the dispersion designs the formula for optimum performance. This end-to-end engineering is the key for functional sophistication of the ink. TAKA’s highly sophisticated metallic ink enables you to generate unique POP printing with strong power of expression.