TAKA Material & Systems Laboratory, inc.

INKJET INK

Water Base Pigment Ink For Textile

Color

Supply Forms

| Cartridge | 220ml・440ml |

|---|---|

| Bottle | 1L・5L・200L |

| Aluminum Pack | 220ml・440ml・1L |

Inkjet Printer Ink Design with TAKA Water-base White Dispersion Liquid

TAKA has engineered Water-Base White Inkjet Ink for Garment Printer using TAKA’s Water-base White Dispersion Liquid.

To engineer Inkjet Ink, composition must be optimized to accomplish missions such as:

1. to secure stability of ink droplet discharge by matching with inkjet printer head

2. to establish long-term printing stability by matching with printer itself

3.Wash-fastness

that is one of the important feature of the garment printer.

Value from TAKA Water-based White Inkjet Ink for Garment Printers

When the power of an inkjet printer is turned off, and the printer is left to sit unused for an extended period of time, the ink composition and physical properties change due to factors such as sedimentation of the pigment in the head and moisture evaporation. If the printer is turned back on in that state, ink discharge problems may occur.

White inks in particular tend to exhibit discharge problems in a relatively short amount of time due to the use of pigments such as titanium oxide which have a high specific gravity and easily undergo sedimentation.

When inks containing pigments that strongly aggregate when sedimented are used, the aggregates that are formed can clog the ink head, cause a curved flight of the discharged ink due to adherence around the nozzle, and result in permanent printer damage that cannot be repaired.

However, white ink from TAKA Material & Systems Laboratory Inc. features a unique ink composition that impedes the formation of aggregates from sedimented pigment.

Therefore, even if discharge problems occur after an inkjet printer that has been left unused for a long period of time is turned back on, the printing quality can be naturally restored in the process of continued printing, or it can be easily recovered through a simple manual cleaning operation, and permanent damage can be avoided. In addition, there is no excessive waste of ink in the process of recovering from discharge problems./p>

Development of Water-base White Dispersion for Inkjet Printer Based on TL-COLOR Technology

In general, titanium-oxide is used as a white-ink colorant. However, titanium-oxide is considered challenging to be used for inkjet ink due to the following characteristics:

1. Easy to precipitate in liquid as the specific gravity is high

2. Difficult to micro-particulate as the particle is very hard

Specifically in water-based inkjet ink, precipitated particles become agglomerated. Even Re-dispersion with agitation mechanism implemented inside ink path of printers can not reverse the coarsened particles to its original size, causing clogged printer nozzles.

Value Proposition of TAKA Water-base White Dispersion

TAKA Water-base White Dispersion, developed by TAKA Material & Systems Laboratory, inc. enables engineering of Water-base White Inkjet Ink suitable for industrial application.

Innovative Technology

Highly-concentrated, stable dispersion liquid has been achieved by precise control of particle size and special surface treatment in the production process of titanium-oxide water-based dispersion.

This enables us to provide dispersion liquid for water-base inkjet ink that is less subject to nozzle-clogging, and that can satisfy requirements for white-color ink that is largely used for garment printers.

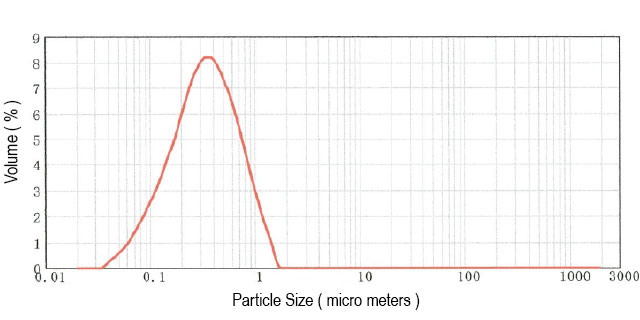

Particle Size Distribution of TAKA Water-Base White Dispersion

Particle size of TAKA Water-Base White Dispersion distributes around 350 nm with small range of variation.

Particle Size Distribution of TAKA Water-Base White Dispersion